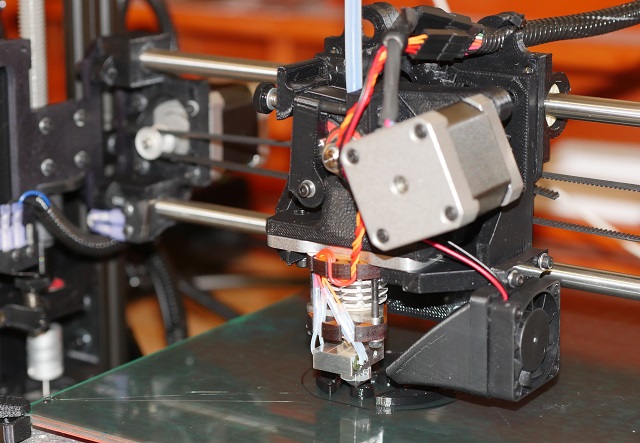

Materials for flexible electronics and soft robots are now 3D printable

04/22/2018 / By David Williams

Researchers from the Oregon State University‘s College of Engineers reportedly developed a method of using 3D printing to produce certain alloys that can be used to create stretchable electronics, flexible screens, and other types of gadgets and devices. This is based on detailed information provided by the researchers themselves, who said that the results of their research could eventually lead to the construction of tall and sophisticated structures with the aid of 3D printing technology.

Based on online reports, the research team were able to get the results that they did by putting nickel nanoparticles into a liquid metal, galinstan, in order to thicken it into a paste that offered a suitable consistency that could be useful for additive manufacturing. The details of their methods, as well as the findings of their research, were recently published in the journal Advanced Materials Technologies, under the title, “Rheological Modification of Liquid Metal for Additive Manufacturing of Stretchable Electronics.”

According to Yigit Mengüç, an assistant professor of mechanical engineering and a co-author on the study, their method finds a way around a conventionally unworkable process. “The runny alloy was impossible to layer into tall structures,” he said. “With the paste-like texture, it can be layered while maintaining its capacity to flow, and to stretch inside of rubber tubes. We demonstrated the potential of our discovery by 3D printing a very stretchy two-layered circuit whose layers weave in and out of each other without touching.”

It is said that gallium alloys are currently being used as the conductive material in standard flexible electronics, mainly due to some of their more useful characteristics. These include their low toxicity levels and good conductivity levels, along with their “self-healing” properties. To top it all off, they’re quite inexpensive.

And the thing with current methods is that the printability of alloys was restricted to being only two-dimensional. Now for the new method, the researchers used sonication – meaning the energy of sound – in order to mix the nickel particles with the oxidized gallium in the liquid metal.

According to Dogan Yirmibesoglu, a co-author on the study, their method is the key to opening the door to many opportunities. “Liquid metal printing is integral to the flexible electronics field,” he said. “Additive manufacturing enables fast fabrication of intricate designs and circuitry.”

As far as the future of their new material solution is concerned, Yirmibesoglu thinks that things are looking bright. He said that their breakthrough effectively enables the creation of soft robots that are ready for operation and will just walk out of the printer. (Related: Study: Robots could soon replace most government workers.)

Meanwhile, Uranbileg Daalkhaijav, a co-author on the study, the gallium alloy paste brings a few new things to the table. “It can be made easily and quickly,” he said. “The structural change is permanent, the electrical properties of the paste are comparable to pure liquid metal, and the paste retains self-healing characteristics.”

Hopefully, the researchers can further refine their methods, resulting in an even better solution that works more effectively while still being relatively inexpensive and quick to make. That might end up helping to advance the field of robotics a lot faster.

Read more about the future of robotics technology in Robots.news.

Sources include:

Tagged Under: 3D printed metal alloy, 3D printing, Chemistry, electronics, flexible electronics, flexible tech, future tech, gadgets and devices, gallium alloys liquid metal printing, inventions, liquid metal, robot technology, robotics, self-healing, soft robots, stretchable tech

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 COMPUTING NEWS